Transforming your fulfillment process from manual labor to automated precision, saving time and boosting customer satisfaction.

As a Shopify merchant, I know firsthand the challenges of scaling an e-commerce business.

One area that often becomes a bottleneck, especially as order volumes grow, is packaging and fulfillment.

Manually packing orders can be incredibly time-consuming, prone to errors, and a significant drain on resources.

That’s why I’ve been exploring and implementing various packaging automation options, and I want to share what I’ve learned with you.

Automating your packaging process isn’t just about speed; it’s about accuracy, cost reduction, and ultimately, a better customer experience.

It allows you to reallocate valuable human resources to more strategic tasks, like marketing or product development.

So, what exactly does packaging automation entail for a Shopify store?

It ranges from simple software integrations to sophisticated robotic systems, depending on your scale and budget.

Let’s dive into the different levels and types of automation you can consider.

The first step often involves software automation.

This includes integrating your Shopify store with order management systems (OMS) or enterprise resource planning (ERP) software.

These systems can automatically pull order data, update inventory, and even trigger shipping label generation.

Many Shopify apps, like ShipStation, EasyPost, or Shippo, specialize in automating shipping label creation.

They can automatically select the best shipping rate, print labels in bulk, and even send tracking information back to your customers.

This eliminates manual data entry, reducing errors and speeding up the entire process.

Automated packing slip generation is another simple yet effective software solution.

Instead of manually writing out order details, a system can instantly create a professional packing slip with all necessary information.

Some advanced software can even suggest optimal box sizes based on product dimensions, minimizing void fill and shipping costs.

Moving beyond software, we enter the realm of hardware automation.

For businesses with moderate to high volumes, automated label applicators can be a game-changer.

These machines precisely apply shipping labels to packages, much faster and more consistently than human hands.

Void fill machines are another popular hardware automation.

Instead of manually crumpling paper or pulling bubble wrap, these machines quickly dispense air pillows or paper void fill.

This protects your products during transit and presents a professional unboxing experience.

Automated taping machines can seal boxes quickly and uniformly, ensuring secure packaging.

For very high-volume operations, you might consider automated box erectors and sealers.

These machines can fold and tape boxes, ready for products to be placed inside, or seal them once packed.

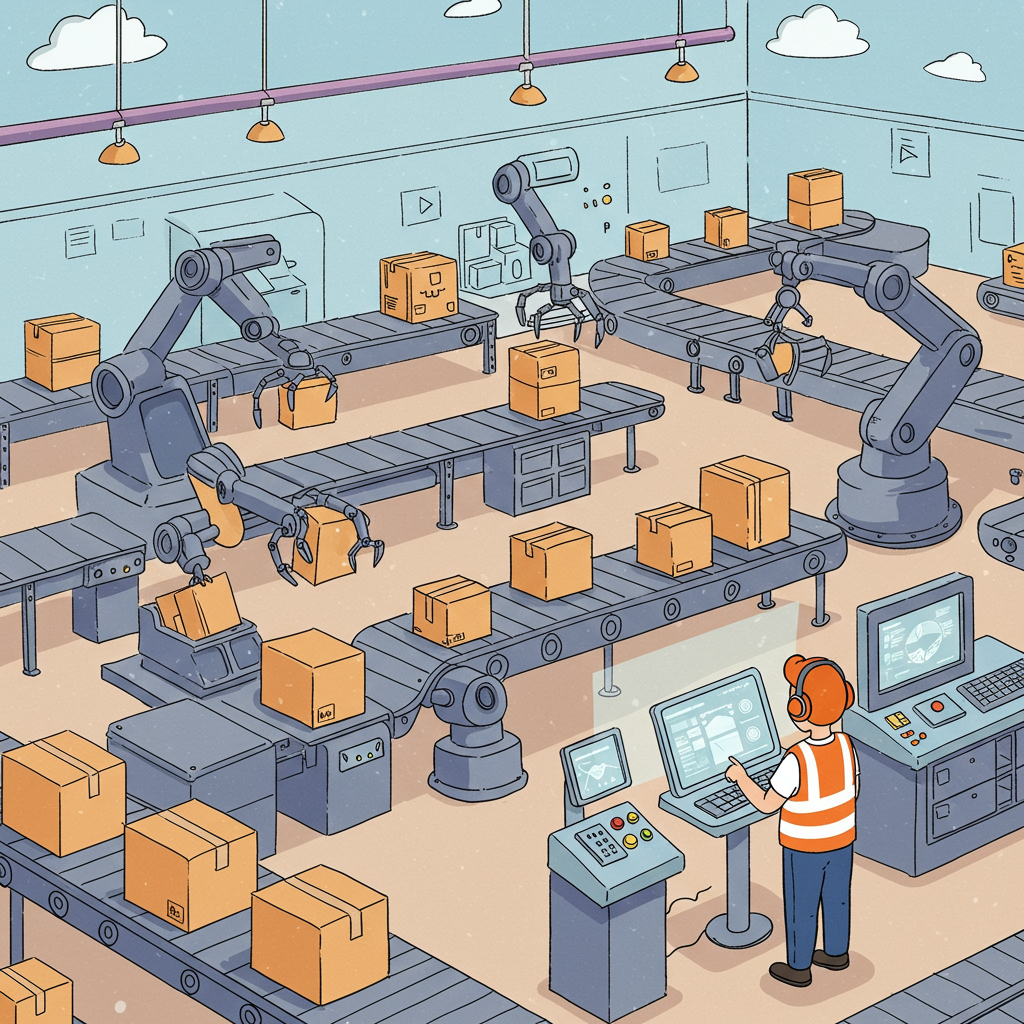

The pinnacle of packaging automation involves robotic picking and packing systems.

While a significant investment, these robots can identify, pick, and place products into boxes with incredible speed and accuracy.

They are ideal for businesses with standardized products and extremely high throughput.

Conveyor systems, often integrated with other automated machinery, move packages efficiently through your fulfillment center.

They reduce the need for manual transport and streamline the flow of goods.

Another powerful automation strategy is leveraging Third-Party Logistics (3PL) providers.

When you outsource your fulfillment to a 3PL, you’re essentially tapping into their existing automated infrastructure.

They handle everything from warehousing and inventory management to picking, packing, and shipping.

Many 3PLs utilize advanced robotics, automated sorting, and efficient packing lines that would be cost-prohibitive for individual merchants.

This allows you to scale your operations without the massive upfront investment in equipment or personnel.

Choosing the right automation solution depends on several factors.

First, assess your current order volume and projected growth.

What’s your budget for initial investment and ongoing maintenance?

Consider the nature of your products: are they fragile, oddly shaped, or require special handling?

Most importantly, ensure any solution integrates seamlessly with your Shopify store to maintain data flow.

My advice is to start small and scale up.

Perhaps begin with automated label printing and then explore void fill machines.

Pilot new systems to ensure they genuinely improve efficiency before full implementation.

The benefits of packaging automation are clear: significant time savings, reduced labor costs, fewer shipping errors, and faster delivery times.

This all contributes to higher customer satisfaction and repeat business.

It frees you up to focus on growing your brand, rather than getting bogged down in operational minutiae.

What do you think about this article? Have you implemented any packaging automation in your Shopify store?

Embracing automation is not just about keeping up; it’s about getting ahead in the competitive e-commerce landscape.

It’s an investment in your business’s future, allowing you to scale efficiently and profitably.

I encourage you to explore these options and see how they can transform your Shopify fulfillment process.

The future of e-commerce is automated, and your business can be a part of it.